Switchless Pneumatic Machine

10,00 € -Excl. Tax

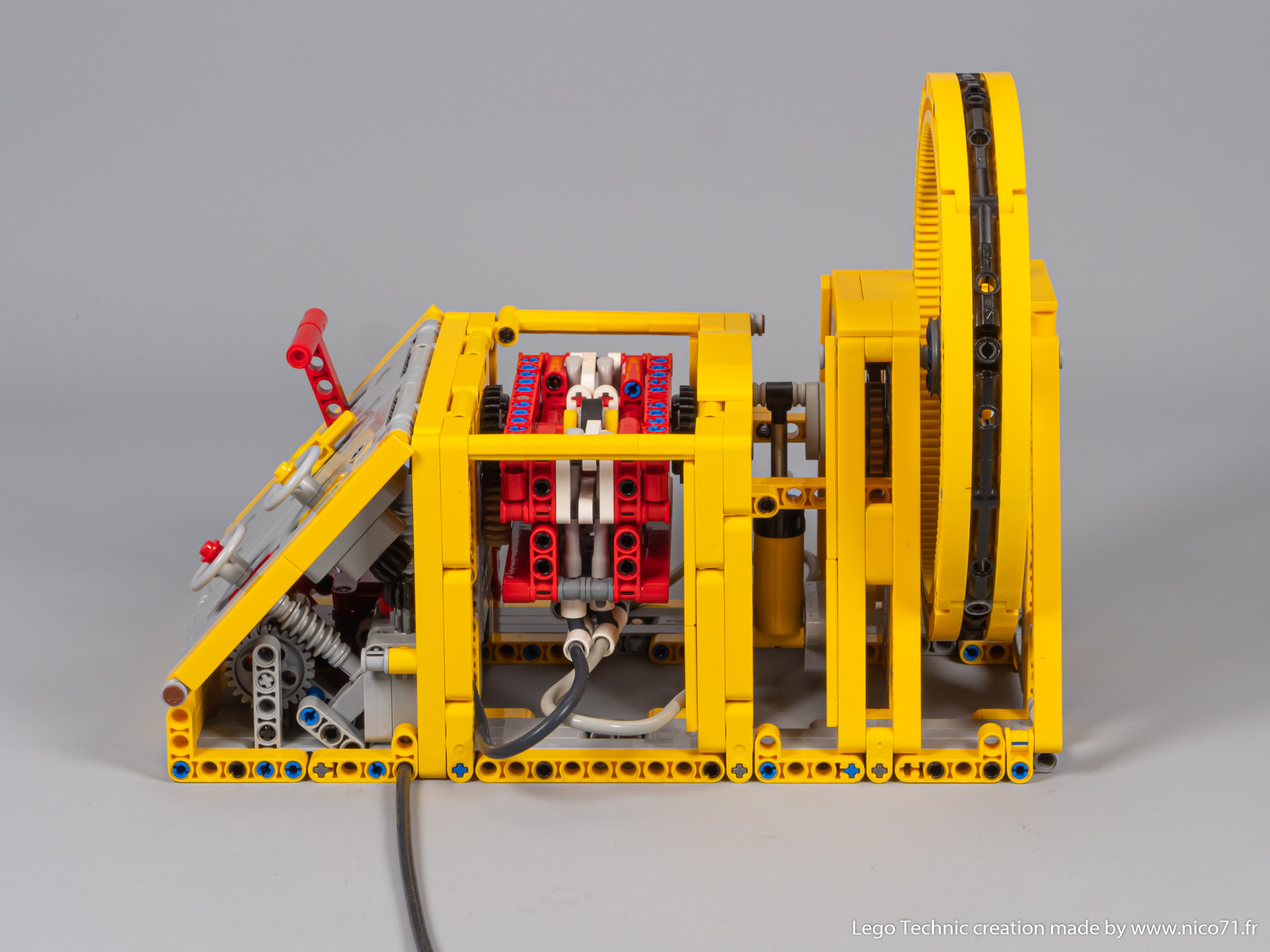

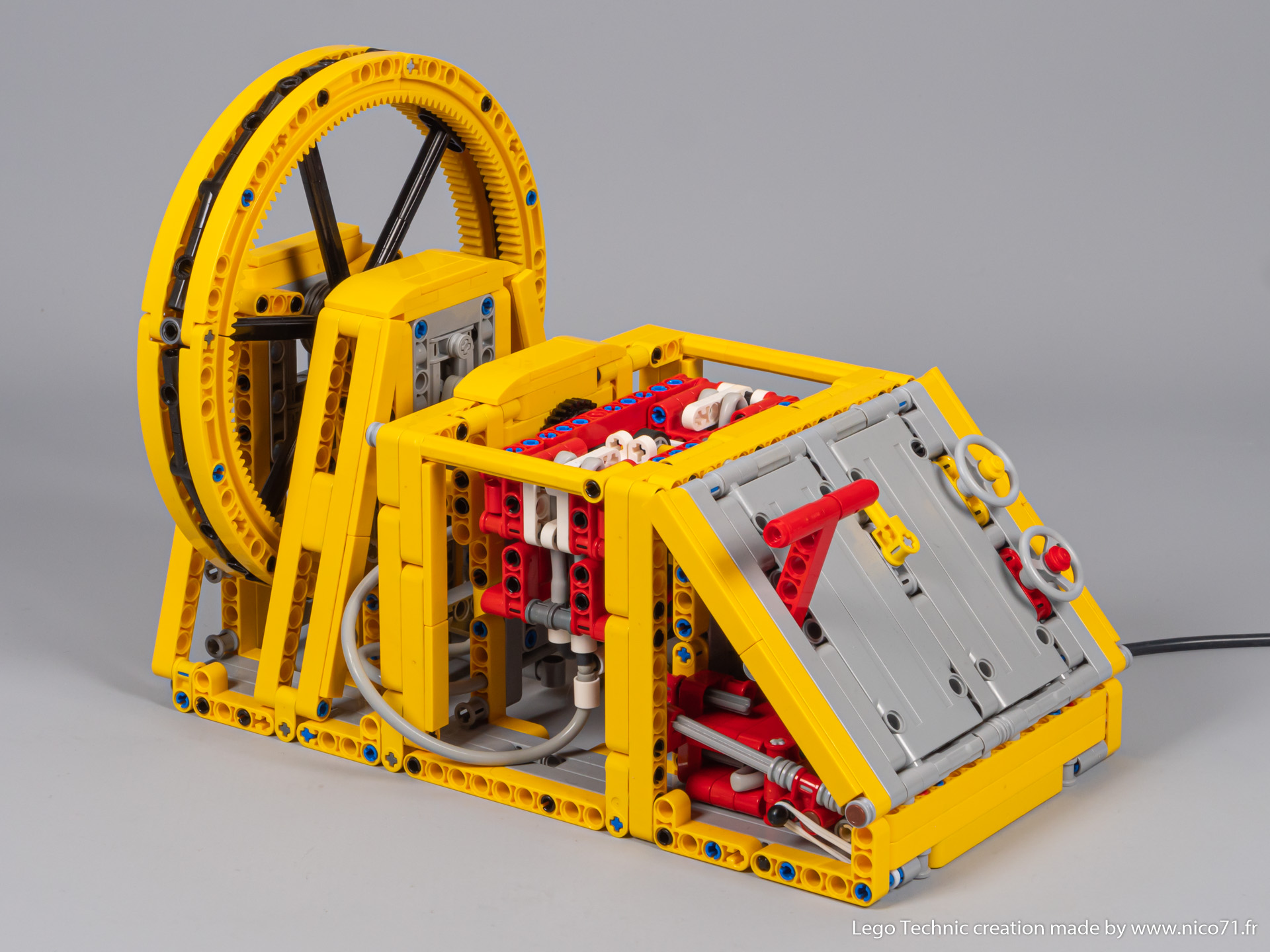

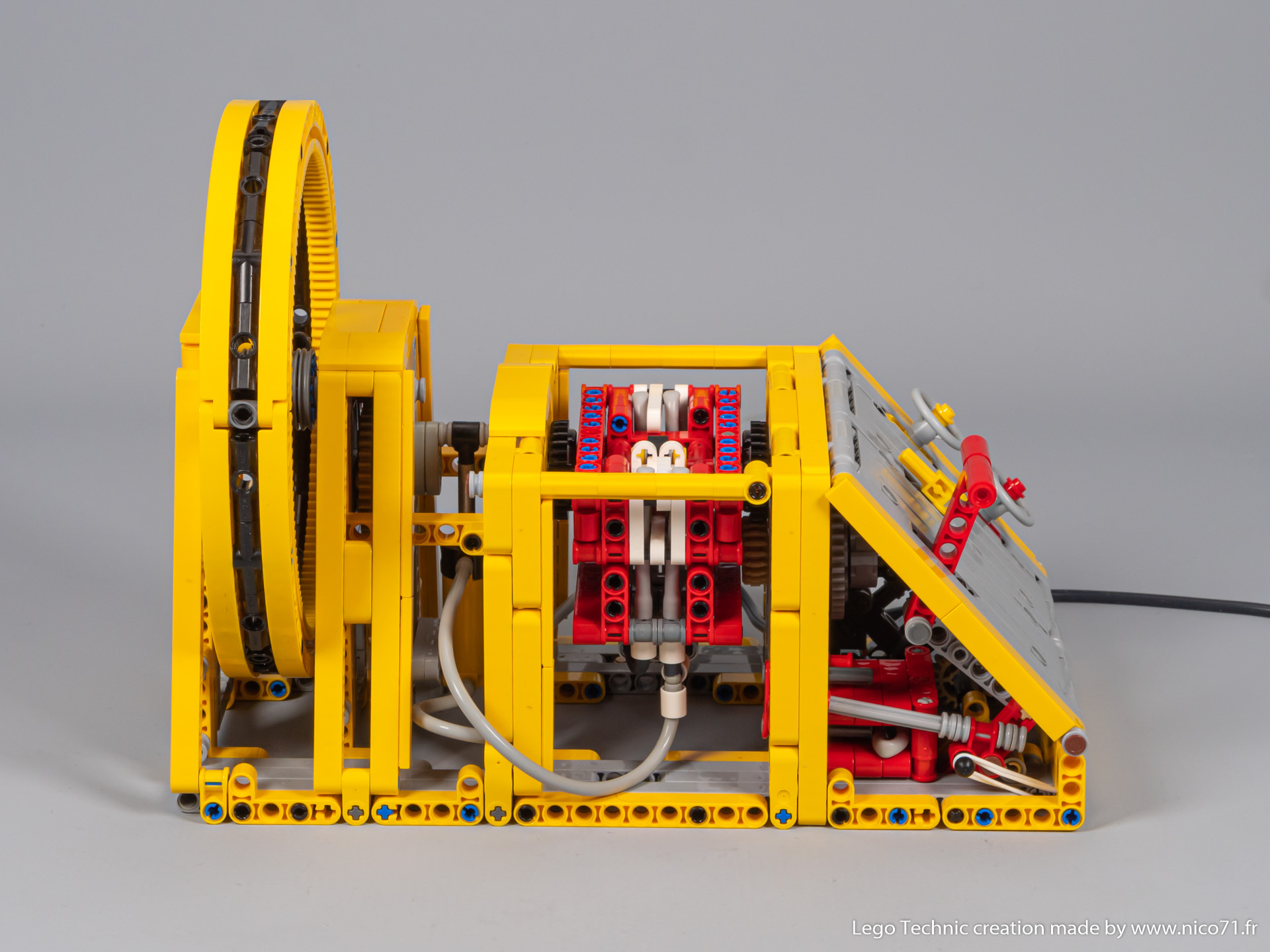

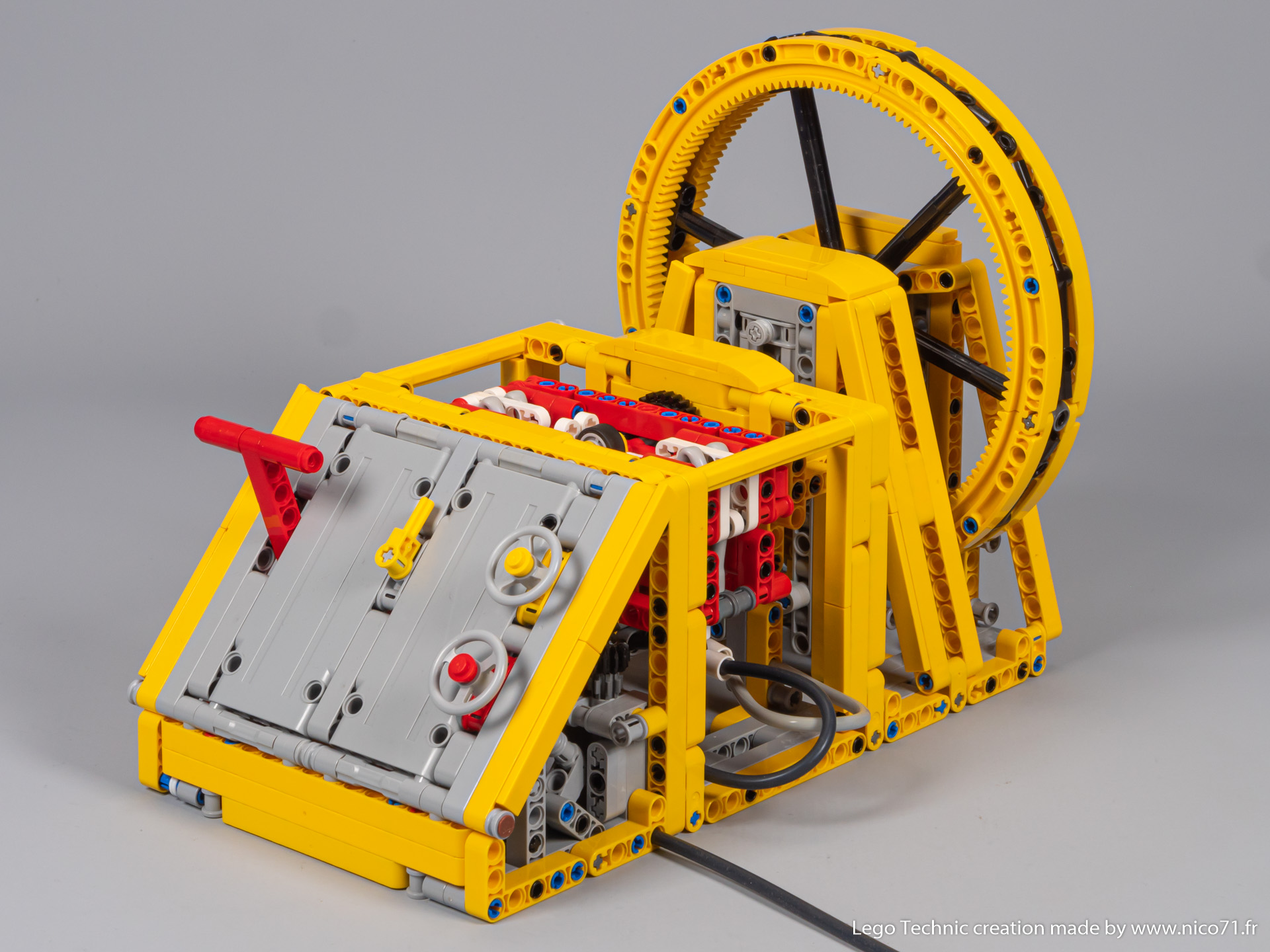

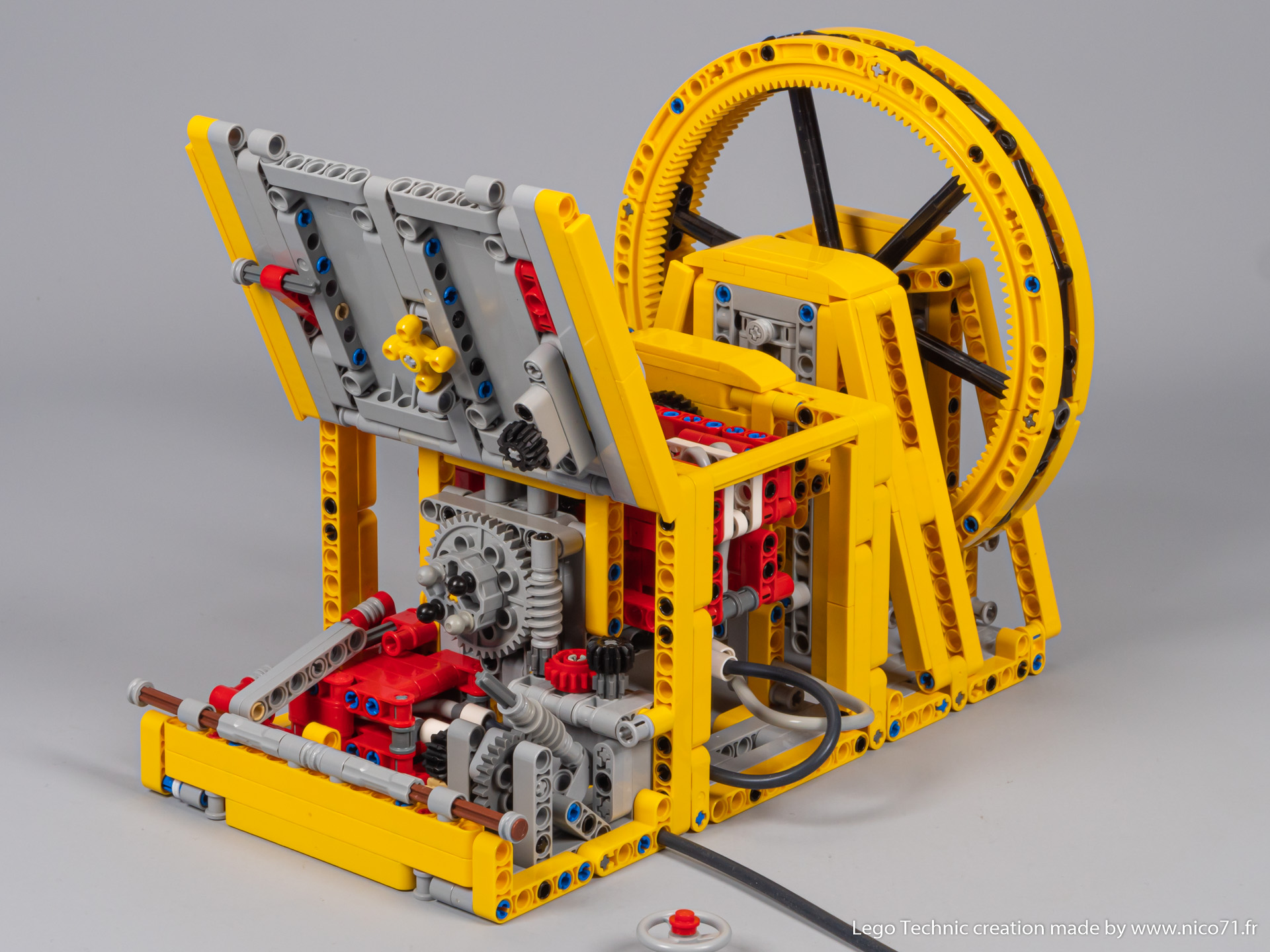

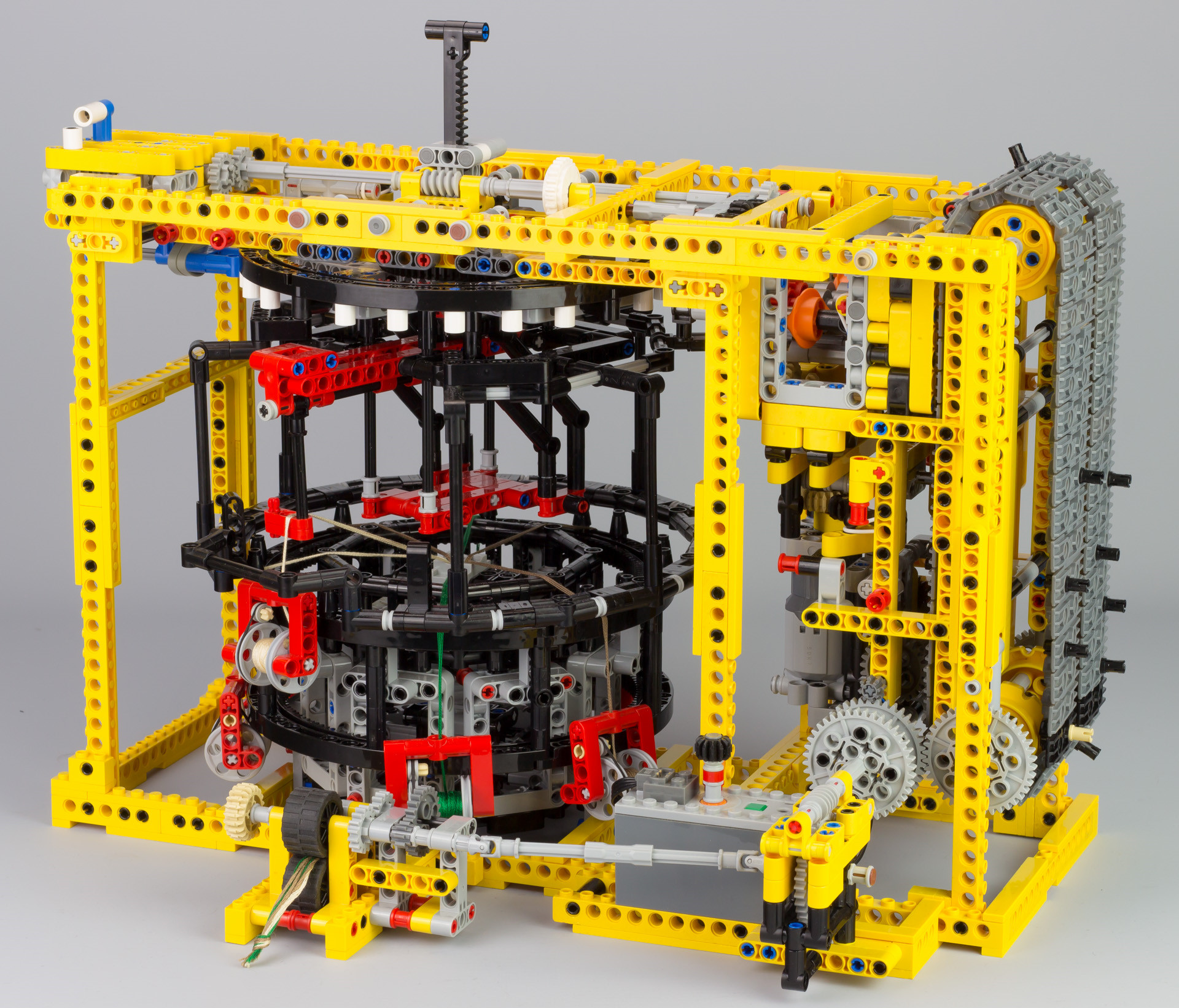

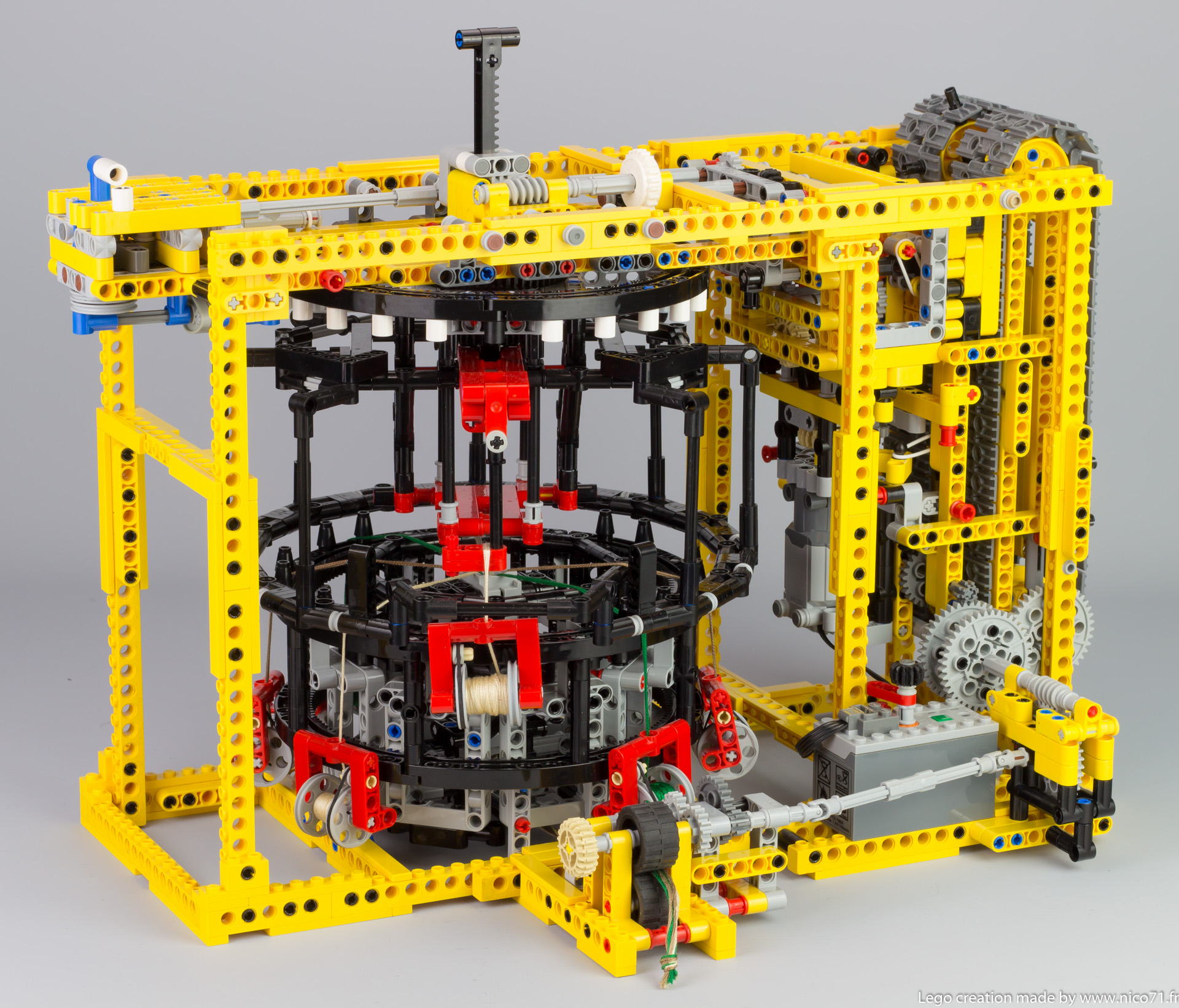

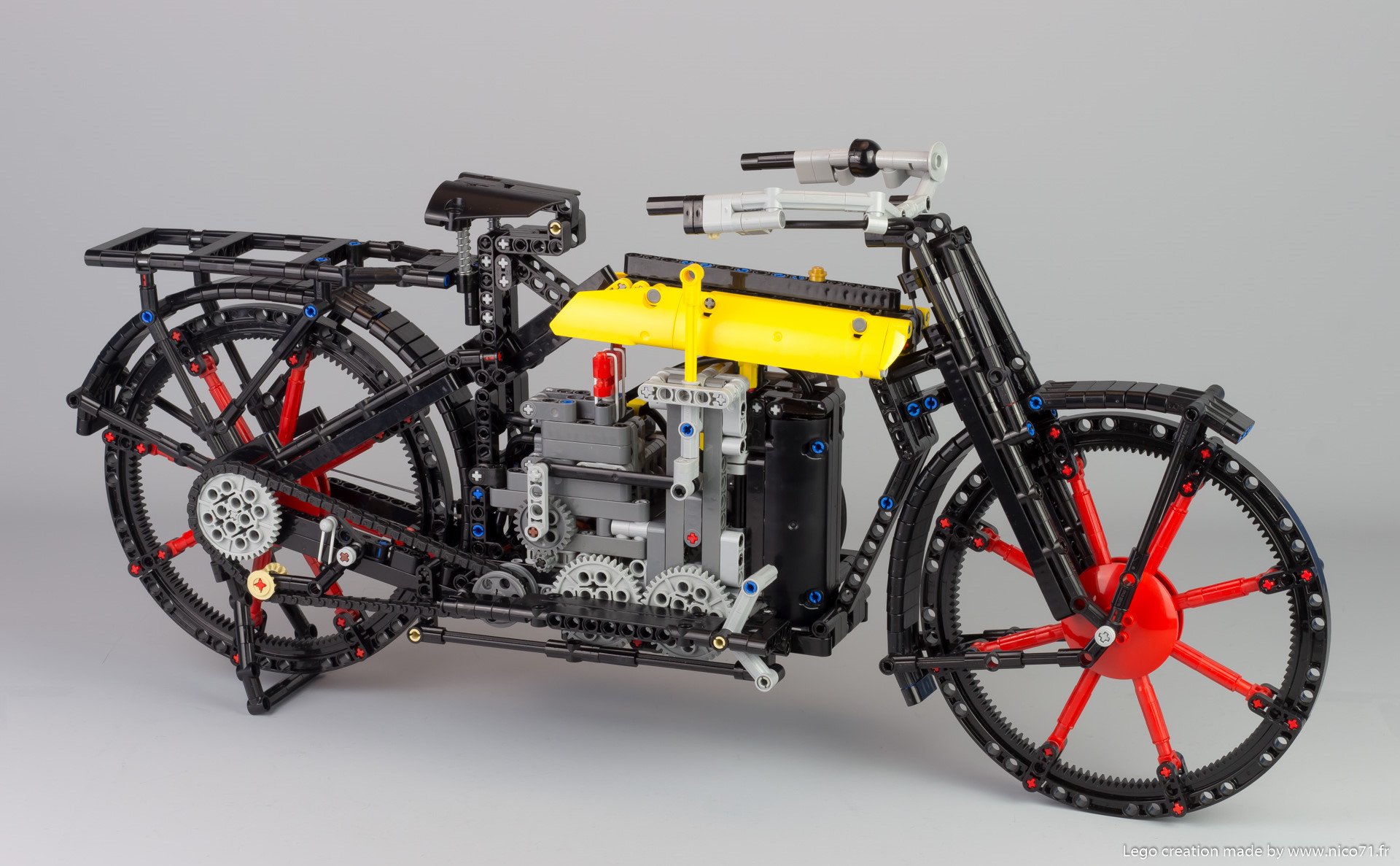

A LEGO Technic Pneumatic Switchless Machine with adjustable timing, working throttle, with idle mechanism, and openable controls panel.

Video Presentation

How it works

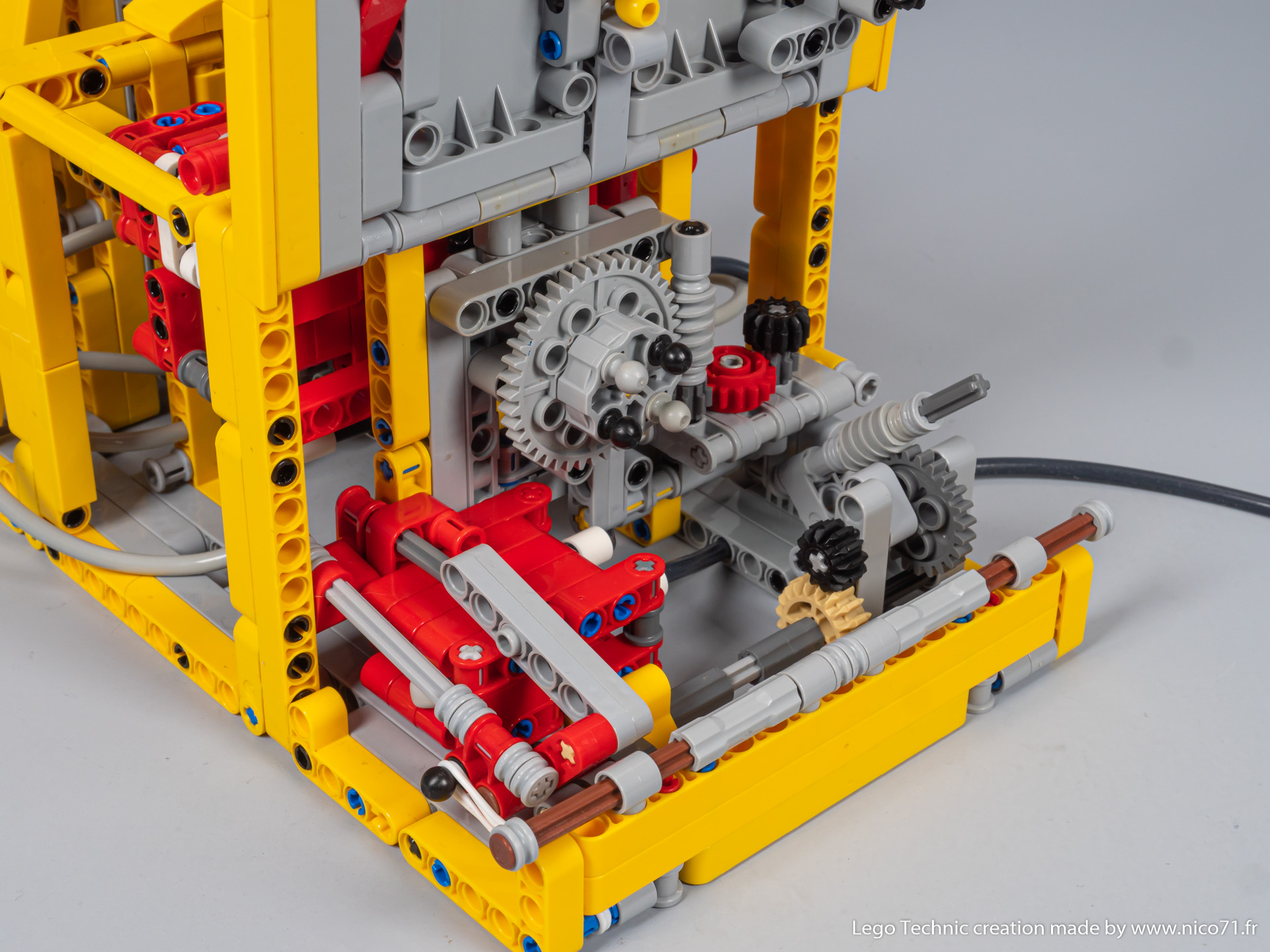

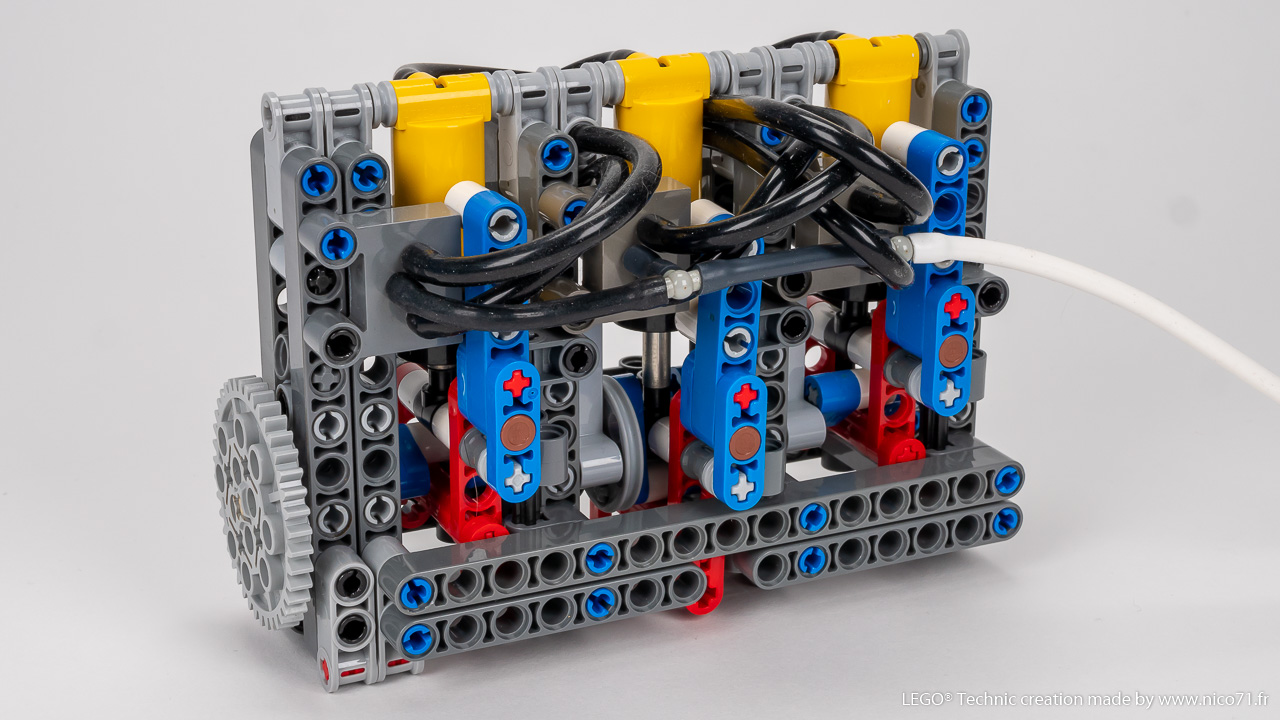

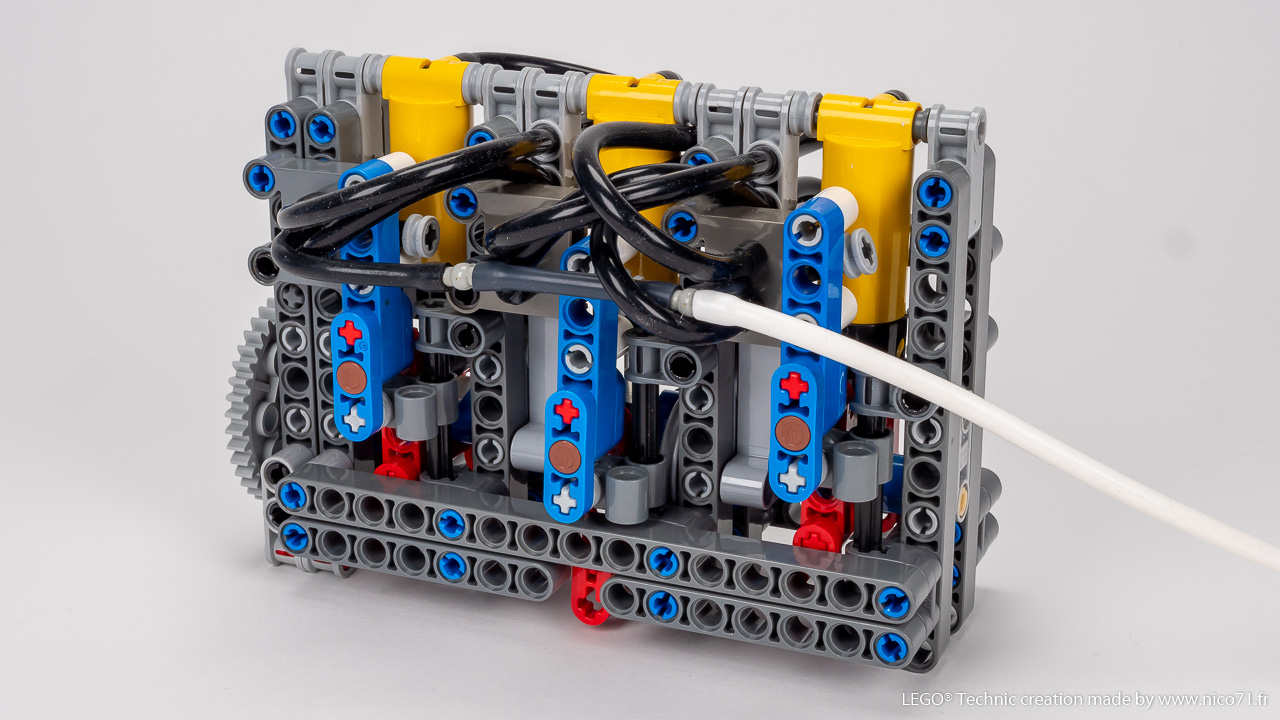

This engine is build around a single pneumatic cylinder, with air distribution using switchless valves. The switchless valves are composed of 2 hose loops by cylinder chambers, which are operated by pushers with a single camshaft, enabling to pinch the hose to restrict the air flow.

The whole valve assembly can rotate around the camshaft, enabling a rotation angle offset between the camshaft assembly and the crankshaft, in order to adjust precisely the timing (ignition point of internal combustion engine). The yellow wheel on the front panel controls the timing angle, with a visual indicator as the yellow connector.

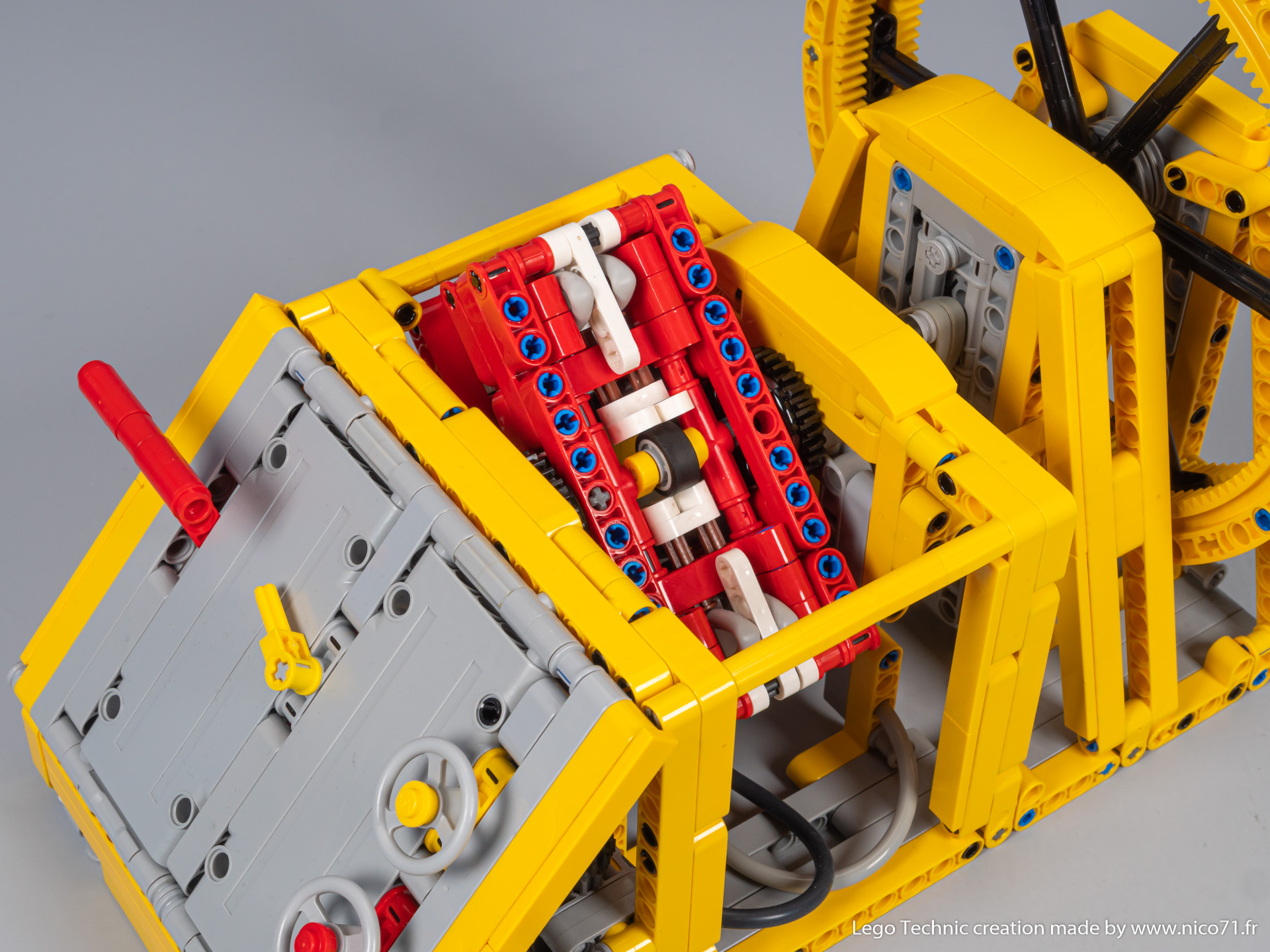

The model is also equipped with working throttle, which works on the same principle as the switchless valve, by using a pinched loop to restrict the air flow. It is operated by linkage which is connected to the red throttle with rubber bands. Then, a idle mechanism, which acts as a adjustable endstop enables to set up the idle of the engine, which is operated by the red wheel. To finish, the control panel can be open to see the internal mechanism.

If you want to build a simpler version of this machine, have a look to the simple switchless engine.

How to build ?

You only need the parts and the instructions. You can purchase the PDF instructions on this shop and build it with your own LEGO parts. The instructions contain the partlist at the end, but you can check individually on ![]() Rebrickable.

Rebrickable.

Please note that you need to have you own source or air (2 bar with constant flow). You can use :

- 4x pump LEGO like this one

- Use a LEGO compressor according to the specs

- Use a electrical compressor like automotive compressor, industrial or electrical pump, you will need to put the air in the LEGO hose with . You can use a ball needle.

- Use a hand pump with ball needle.

Max speed at 4 bars was 160RPM so 800RPM on the flywheel.

The hose for the timing assembly have to be carefully chosen (4x 9cm lenght). They have to be soft enough to have an easy pinching and strong enough to handle the pressure. For instance, the last hoses in the 42100 are glossy and hard to pinch, the very old pneumatic hoses from 90’s is too soft and do not handle the pressure. The ideal hoses are those which come from the sets from some year like the 8436, or the 8455 (mine comes from this set), you can use also the hose from the 8110, 42043 if they are not the glossy version.

You can use other hoses but you will need to increase the pressure if the hose is too hard to pinch and reduce if it is too soft (with of course limits). As I have not tested, I can not certify it will work with every hose. Nevertheless, the one from Blokbricks works fine and can be purchased in meter.

I have not seen any wear on the hose, even if they tend to keep the shape of the loop some time after dismantling, they recover their original shape without any leak or damage after some time. But I think it can be damage if they rest for a long time on display with no pressure. So if you display this creation, remove the U shape assembly with white fork to loosen the loop.

About this product

Instructions preview

Additional information

| Model Size | 26cm (L) x 17cm (W) x 19cm (H) |

|---|---|

| Color | Yellow |

| Categories | All, Machine |

| Motorized | No |

| Building Difficulty | Medium |

| Piece Count | 993 |

| Bill Of Material | https://rebrickable.com/mocs/MOC-128169/Nico71/switchless-pneumatic-machine/#parts |

| Purchased File | PDF Instructions (About 121 pages / 132mo) |