Lot of people ask me to create the instructions of this basic-working smooth engine, so I did. You can download the High Definition PDF or watch the pictures.

The video :

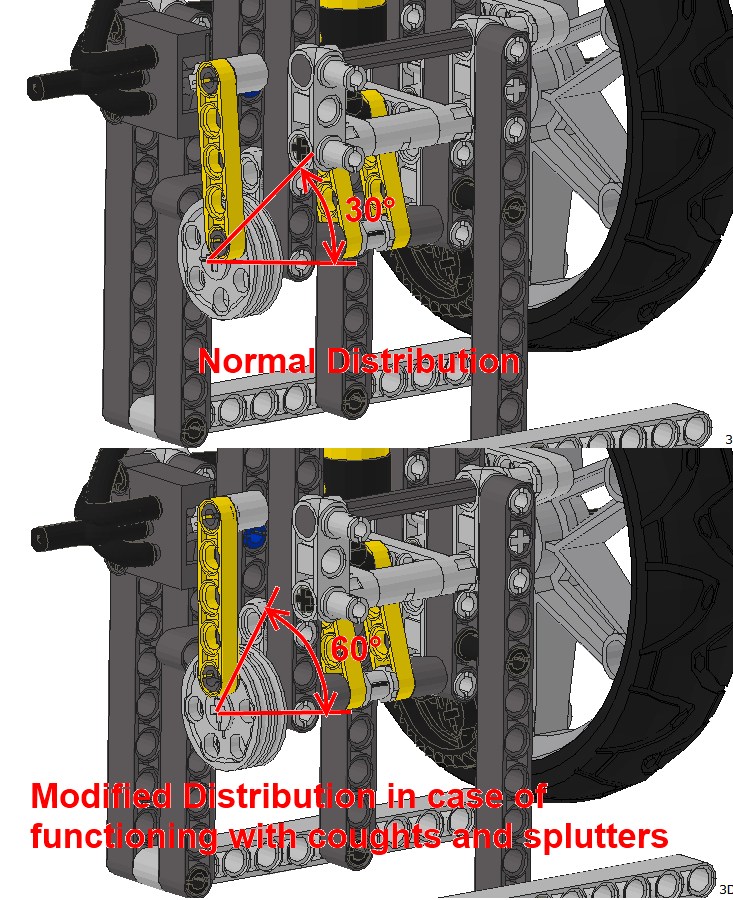

The functioning depends of the usury of your pneumatic parts. A smooth switch and cylinder are recommended. If your engine works with coughts and splutters, use the modified distribution. Also : keep in mind that the engine works in only one direction of rotation.

I have created the building instructions. You can download for free :

Single Pneumatic Engine

0,00 € -Excl. Tax

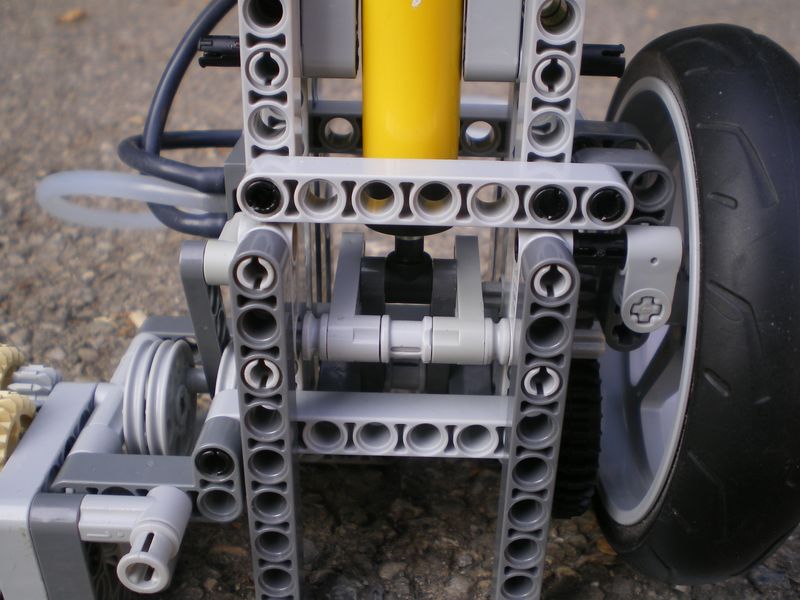

Single Pneumatic LEGO Technic engine with unmodified parts, that I used on my manipulator. With free instructions.

Designed in 2011. Powered by SR 3DBuilder, Mlcad and Lpub.

(32) Comments

Hmmm very nice 3d renderings

Of your engine desighn am used to con rods in valve train trying to get my head around scotch yoke set up….your instructions a god s

end…inovation is the mother of nesecity

Ok, I’ll give that a try. Thanks for responding!

Hello, I don’t use lubricant for my cylinder and switch but if you want, you can use silicone oil, this is the only raw material whicb doesn’t damage the ABS and plastic and ensure a good lubrification. Give up the standard oil or grease or vaseline, it doesn’t work with our lego. Regards.

Hey nico, how and what lubricant could I use on my switches and cylinders? I have tried so many times to make pneumatic engines and the have failed, prob due to the switch or cylinder. Can you please help me or director in a direction?

Hi Nico,

what is step 12&13 in the instructions? It looks like I’ll need 900 blocks of air to make it work, but I only have around 600. I’m sad :).

really nice!

Awesome!!!!!!!!!!!!!!!

You can try on bricklink.com

I want to make this for a school project. Can you please help me find a place where I can buy all these parts? I have not been able to find them. Thank you!

I only have an old swich, can i use that too?

Hey I am almost done but I got a old switch without the holes. I cannot find any switches and bricklink won’t work for me. Any other ideas?

Hi everybdy,

After 25 years out of LEGO I’ve just built this simple LPE with my new 8110 Unimog pneumatic cilinders and valves, using a Unimog wheel and tyre as a flywheel. Also built an electric compressor to provide some “petrol” (Two big pumps w/o the springs & one XL motor): not very smooth, but it works.

It’s easy to double it, using one valve to control two clinders, you’ll only need another big wheel to increase inertia and keep it going ;-D

Many thanks to you, Nico, let’s try whith your inline three. If I can do it a six I’ll buld a BMW around xD

Hello, I have tried to build this engine, and I was pretty successful, however, it does not work. It just can’t get over the middle position of the switch. I also tried to modify the switch, but I failed(somehow) and it leaks air now, so I can’t risk my second switch too. I just wanted to ask, can I make this engine work WITHOUT modifying anything at all? And do I need to use the SAME flywheel, or can I use a wheel with the same diameter? This situation is pretty urgent please reply as soon as you can. Thank you!

is there a way the one can get the lpe to work on a cylender and switch?

thanks

In the future I may order some cylinders. What i would do is modify it with gears and a second pump to make it so that it can pump itself and keep going. I would use the gears to make the second pump spin faster than the pump powering it. But the second pump would be a mini one so it would have to go fast to pump anyway.

[…] instance, this classic LPE with 1 cylinder provides 1.3W of power whereas the Nicjasno’s 8 cylinder big block provides 100W, that is […]

You should test with different cylinder and many pumps, the speed is function of the pressure. Regards

if the switch we have is very stiff and does stop the engine, how does one loosen it up?

I don’t think so. Regards

Hey, can this engine work with a hand crank instead of pneumatics?

Thank you Logan.

Thanks!

By the way your models RULE!!!!

I have seen that Bricklink don’t sort the wheel correctly so I have found the wheel with the 8420 catalog

As you can see of the bild of material attached to the post, the reference number is : 32078 Tyre 28×70. Regards

What is the reference number of the big wheel?

Where can i get the big wheel?

Yes, because the engine doesn’t start without the inertia of wheel. The inertia of fly-wheel helps the engine in order to get over the middle position of the switch 🙂

Sorry I don’t have. Generally, if building instructions don’t appeared on my blog, I don’t have them 🙂

I use two hand-pump on the video, maybe your switch is too hard ?

Do you need the big wheel?

Hi,

not sure how else to contact you. My son is very keen to make the caterham csr260. He was wondering if you were able to provide instructions for this car.

hope you can help,

Fiona Williams

it doesent work with lego pump. do you use compressor?

And THANK YOU!!! Your creations and instructions rule!!!

CONGRATULATIONS 😀

Comments are closed.