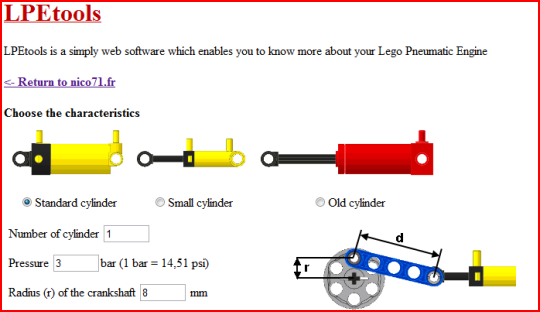

This new tool has been designed to help builders to know more about their Lego Pneumatic Engines. LPEtool manages all the important data : type of cylinder, number, switch, modified or not, dimensions… The tool calculates the maximun power (at maximun speed and pressure) and the average torque which varies with the rotation of the crankshaft.

LPEtools, version 1.0 may 2011

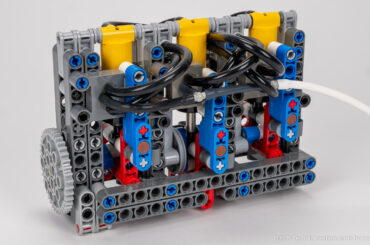

For instance, this classic LPE with 1 cylinder provides 1.3W of power whereas the Nicjasno’s 8 cylinder big block provides 100W, that is surprising but with 1500rpm and 6 bars of pressure, it is quite normal. If you have comment, question of suggestion, feel free to comment in this post.

(5) Comments

Hi this tool is great thanks for shareing! I built my own pneumatic engine an put it in a car https://www.youtube.com/watch?v=p2e8M9ESIBw and acording to your tool its puting out 88W at 3bar@1370RPM (that is as much as i can pump on my bike pump) and it would be way more powerful at 6bar than the V8 at 100W 🙂

Have you made any laborations on what design the most powerful LPE should have?

So according to this tool, LPEs are much more powerful than lego motors, this is great considering I want to make a car with one. Anyway, good job.

@Willisdee: I found that using the old-old style switches are relatively easy to dismantle. You dont really have to cut or break anything. These switches are recognizable by the shorter length of the air inlets (old-old style switches have a length of 5mm, the new-old style switches have a length of 6mm and are a bit conical shaped at the end). Cutting the insides is not too difficult with a sharp knife, once you take your time. Regarding the drilling, I have not yet performed that task (I am still looking for a way to make a nice perpendicular drilling). Hope this helps

I raised a question on the website of LPEpower about their 8-piston engine. My issue was that when you would have the engine running at 1500 rpm (at 6 bars), I think that you may approach sonic flow speed at the main air inlet of the engine (i.e. the first T-junction). This would limit the upper speed of the engine and may give high pressure drops over the tubings. What do you think about it?

Is there a video or instructions for modifying the switches, because all I’ve managed to do is ruin them.

Comments are closed.