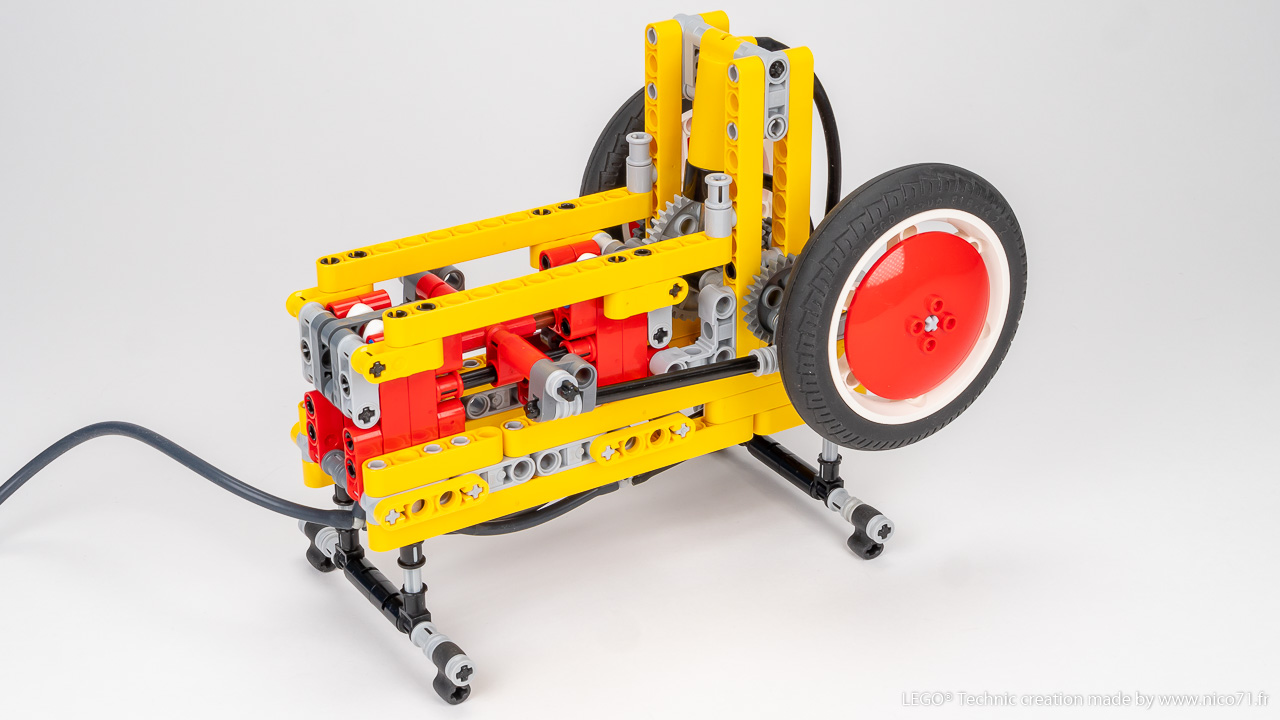

A Lego Pneumatic Engine with a new valve design and non-modified parts.

See it on the shop

(Updated Version from 2023, now with Building Instructions)

Switchless Pneumatic Engine

Context

The problem in making Lego Pneumatic Engine is that the functioning highly depends of the switchs you use. Some switches are smooth to operate and some other no, which may result in a non-functional engine for some people. That is why I wanted to develop a switchless engine with no modified cylinder and at same pressure as Lego pumps can do (3 bars).

I have started by using the classic switchless valve design from some year ago, which works by pinching the hose directly though the diameter. As the official Lego hose is quite hard to pinch, it results in a long lever to operate and requires some force to do. The functioning will also depends of the stiffness of the hose (some LPE makers use non official hose) and the placement of each hose is also really important to avoid leaks. It is better for avoid Lego switch but still not perfect for me.

That is why I wanted to develop my own valve design which required less force and was less dependant of the hose stiffness.

Functioning

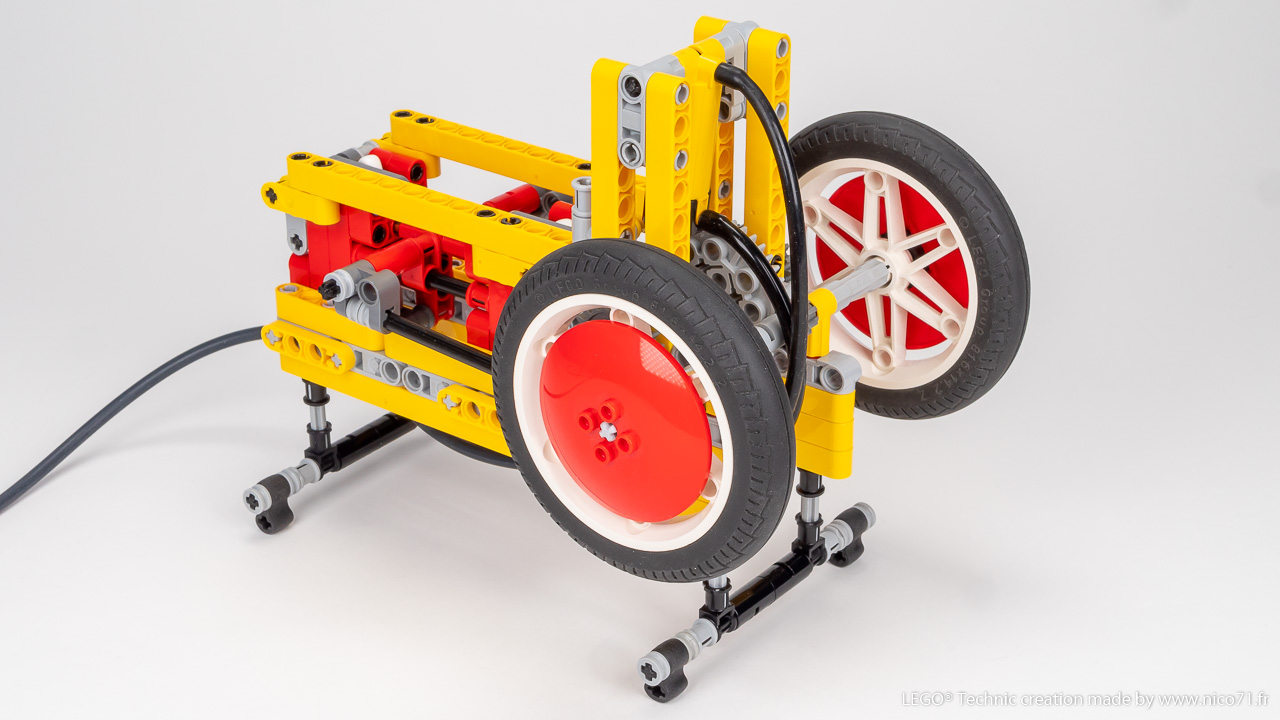

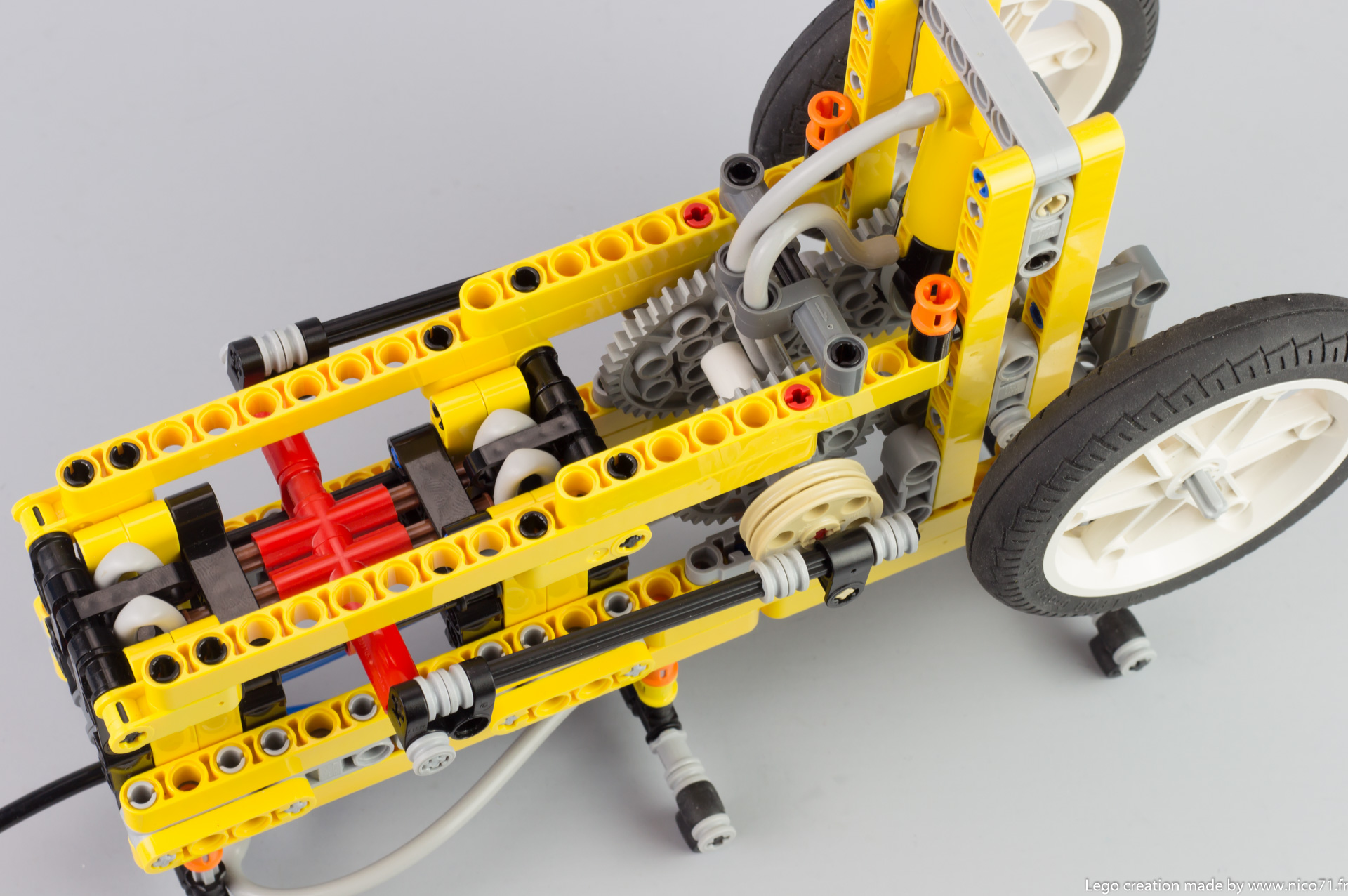

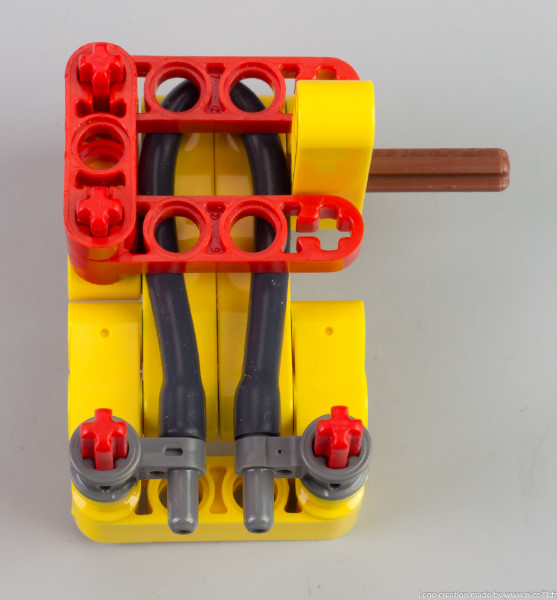

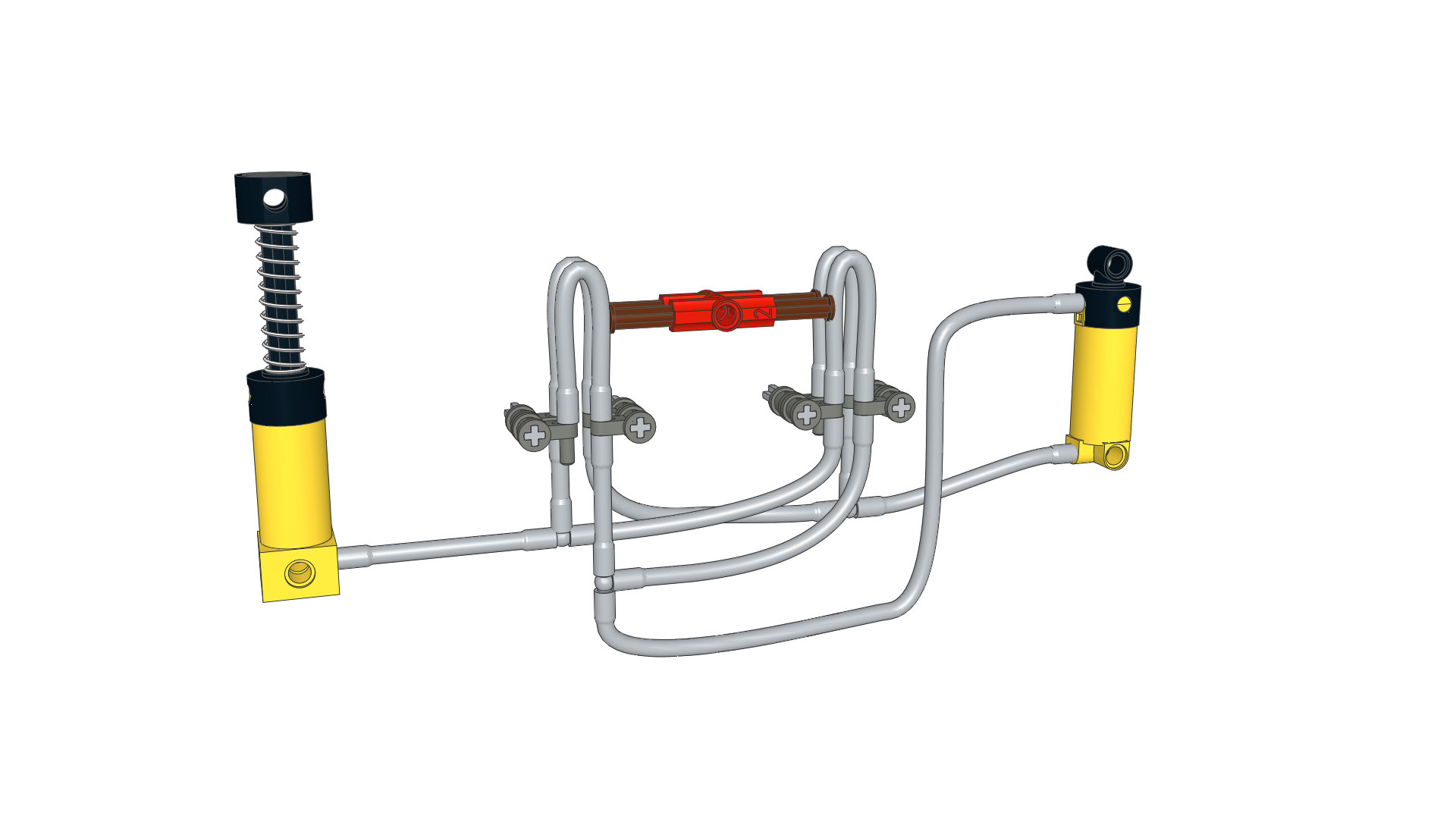

Here is my solution : instead of pinching directly the hose, I use the ability of the hose to pinch itself when you make a tight loop. The loop is attached to T connectors and is located in a frame. An axle with stop pushes it, to tight more or less the loop, which result in a air flow control depending of the position of the pusher.

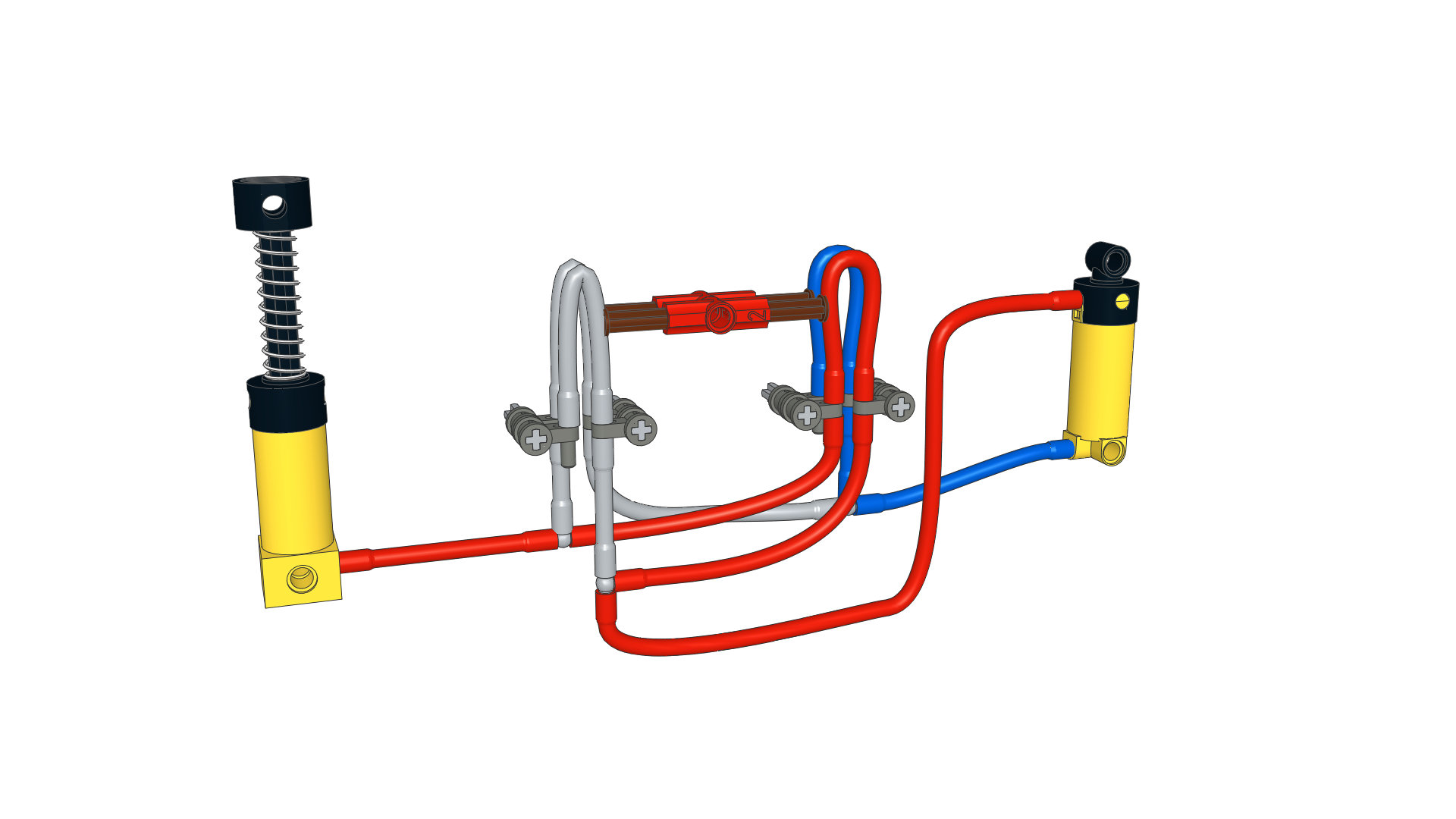

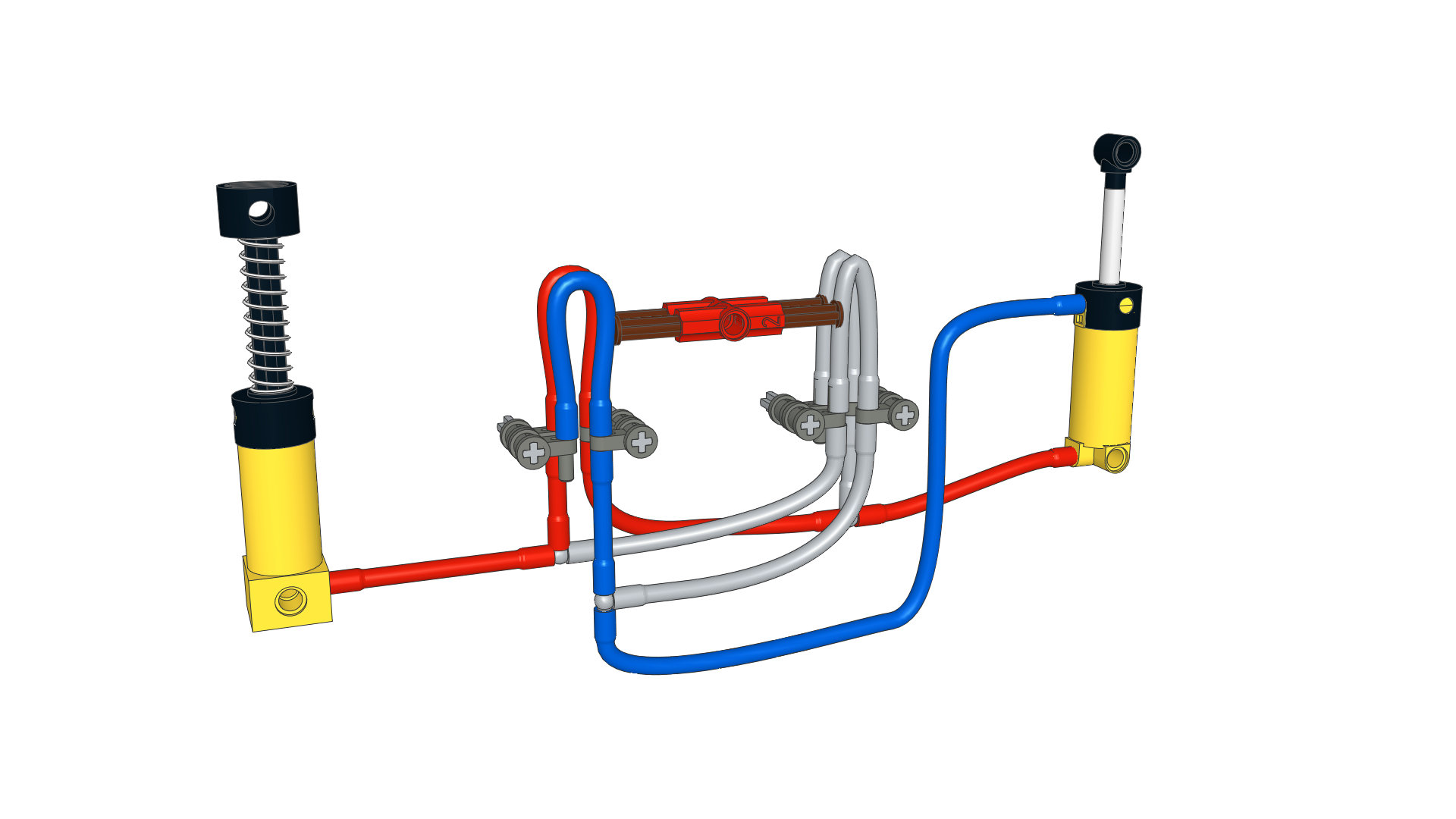

The air flow layout for a single cylinder engine is based on the same principle has previous switchless engine with 4 valves : one admission and one exhaust for each chamber of the cylinder, operated in group of two, alternatively side by side. Here is the coloured schematic of functioning :

On the middle position, the right and left loops are closed, it enables to not lose pressure when the system is operated but it requires also to not stay at this position too long as it works as a dead-point (as every Lego Pneumatic Engine).

When the red pusher is operated to the left, the left loops are pinched, and the right are free. The air can go from the pump to the upper chamber of the cylinder through a loop (red), and the air in the lower chamber can go the exterior by passing in the other loop (blue).

When the red pusher is operated to the right, the right loops are pinched, and the left are free. The air can go to the lower chamber (red), and the air in the upper can go the exterior (blue).

After pusblishing by solution, some people told me about DrDudeNL who has developed an interesting switchless solution too 10 years ago (Reference 1, 2), by using the abilities of the hose to pinch itself, but not in acting directly on a loop as my solution, but more by displacing the two inputs/outputs relatively in translation to force the tube to squeeze. I was not aware of this solution prior developing mine but I wanted to give credit to DrDudeNL for this fantastic idea.

Advantages and drawbacks

This new design for valve has the main advantage to not need high force to operate : the pushers are really easy to push and are less dependant of the stiffness of the Lego hoses. Of course the solution can be extended to multiple cylinder to avoid the inertia wheel. The side by side constructions with center red joiner for pushers enables to operate the switching by a handle/lever or camshaft (see WIP video below).

Of course there is drawback : this valve design is bigger than a classic switch or existing switchless valve and the hose can be more worn as in classic switch use. I have not tried to reduce the size yet as I wanted to show and explain the mechanism, but I am sure that this is possible to improve the size and integration, and reduce the dead-point by using camshaft instead of handle/lever. So fell free to use this design and improve it !

Pictures and video

2023 version of the engine (with instructions)

Old version (sound problem on Youtube)

See it on the shop

(Updated Version from 2023, now with Building Instructions)

Switchless Pneumatic Engine

(6) Comments

I have published the instructions for a simplify switchless engine.

I thought you said you would publish a creation with the engine and instructions.

No instructions for this one, sorry 🙂

Where are the instructions??

Is is not available for this one, as it is a proof of concept. But I will publish a creation with this engine and with instructions.

Where are the building instructions

Comments are closed.